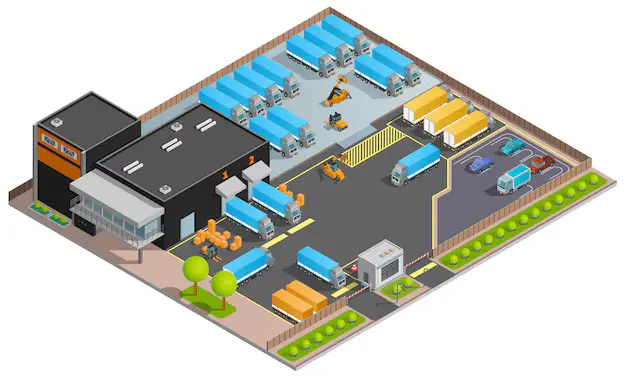

Factory Layout Design

A well-planned factory layout is crucial for smooth operations. Our Factory Layout Design service focuses on:

Customised layouts tailored to your specific production needs.

Optimisation of space to ensure smooth movement of materials, equipment, and staff.

Dedicated zones for raw materials, production, quality control, packaging, and storage.

Workflow efficiency that promotes higher productivity and seamless operations.

Process Flow Mapping

Understanding and visualising the entire production process is key to optimising operations. Our Process Flow Mapping service includes:

Identifying bottlenecks and inefficiencies to propose layout adjustments.

Implementing Lean principles to minimise waste and improve workflow.

Reducing waiting times and ensuring smooth transitions between process stages.

Step-by-step process mapping from raw material intake to final product dispatch.

Visual Display Designs

An effective visual management system enhances workplace efficiency and communication. Our Visual Display Design solutions include:

Signage, colour-coded paths, and floor markings to guide employees through different process areas.

Performance boards displaying key metrics such as production targets, safety indicators, and efficiency statistics.

Visual work instructions that help employees follow standard procedures with clarity.

A culture of accountability and continuous improvement through real-time performance tracking.

✽ What We Offer

Why Choose Qltc for Factory Setup?

Industry Expertise

Years of experience in factory planning, Lean implementation, and process optimisation.

Efficiency-Driven Approach

We create optimised layouts and workflows for maximum productivity.

Customised Solutions

Our designs align with your business goals and operational needs.

Seamless Execution

From planning to implementation, we ensure smooth execution of the factory setup.